Introduction

The manufacture and distribution of sealing wax is the focus of

this business plan, which is based on the production of 13,000 pounds of

sealing wax per month with a potential annual income of US$117,000 or US$9,750

each month.

Production Process

Black sealing wax is most frequently used in post offices and

railways. Rosin and shellac are melted, and then fillers including kaolin,

soapstone, barites, colors, oxides, and oil-soluble organic dyes are added. The

molten substance is then poured into aluminum or gunmetal-colored metal molds.

Bee wax and castor oil are added in small quantities to sealing waxes to

improve their plasticity. After that, the item is put into cartons with 500

grams of sticks.

Market Analysis

In

the postal system, the railroads, all corporate offices, academic institutions,

and government agencies, among other places, sealing wax is in high demand. The

product is in high demand, and there is a very small supply.

International market

Due to

the COVID-19 pandemic, the global Bottle Sealing Wax market size is estimated

to be worth USD

62 million in 2021 and is forecast to a readjusted size of USD 73 million

by 2028 with a CAGR of 2.4Percent during the forecast period 2022-2028

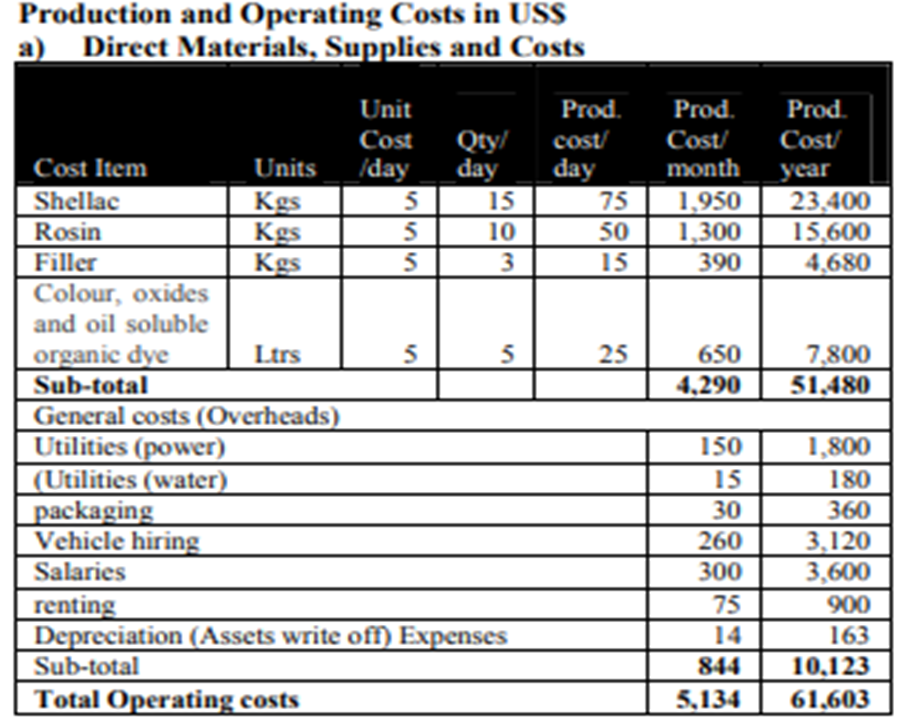

Production costs assumed are for 312 days per year

with a daily capacity of 500 Sealing Wax.

Depreciation (fixed assets write off) assumes 4 years life of assets write

off of 25% per year for all assets.

Direct costs include: materials, supplies and other costs

that directly go into production of the product.

Source of Supply of Raw Materials and

Equipment

Raw

materials and Equipment can be imported from Liberia, China and India.

Government Incentive

Government

is encouraging small scale establishments so as to eradicate poverty.

It's an amazing website that will help you in business ideas, stories of rising different of difference company and motivation

It's an amazing website that will help you in business ideas, stories of rising different of difference company and motivation

No comments

Post a Comment